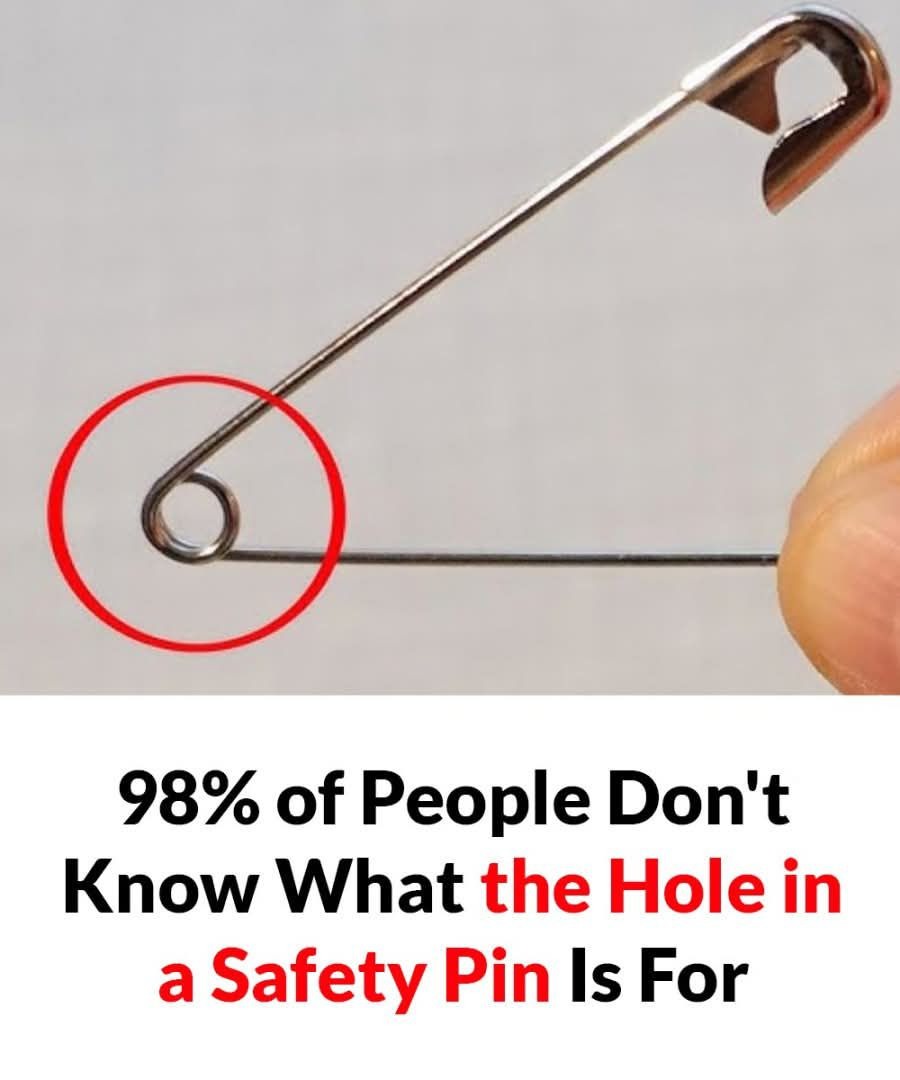

A Rock for Precision Manufacturing

So let’s get a little nerdy for a second (don’t worry, I won’t get too deep). Making a safety pin involves machines shaping the metal wire into that exact shape. During this phase, the hole serves as an anchor point. Without it, it would have been difficult to consistently form that coil. Imagine it as a guiding pinhole. It keeps the wire steady as it’s twisted into that distinctive taut coil that provides the safety pin its snap and strength.

Many spring-based mechanisms use an equivalent feature during assembly to maintain tension and torque across each spring. So as small a detail as it may seem, that little hole is doing a lot of heavy lifting behind the scenes.

Thought It Was Only For Decoration

If you thought the hole was simply… there, you’re not alone. It doesn’t look functional. It’s little, discreet, and if you’re not a mechanical engineer or inclined to question everything, you probably never did. The design is minimalist to the point that it’s easy to not realize how much thought went into it.

Plus, it’s not as if the packaging has a tag saying, “Hey! This is for tension control!” The way most of us do is rip open a pack of safety pins and go to pinning.

Can You Use the Hole for Something Else?

Actually, yes. Though it was not intended for this purpose, some enterprising people use the hole to attach safety pins to other objects — by putting a ribbon through it or weaving a thin piece of wire around it and tacking the pin into something to prevent it from slipping. It’s not its intended use, but hey, it’s a little bonus feature if you’re feeling resourceful.

It is also useful for exact placement in sewing or embroidery. (For stitching projects, some people loop thread through the hole to help anchor the pin better.) Not the original plan, but we love a good multitasker.

Fun Fact: The Safety Pin Was a Happy Accident (Sort Of)

The safety pin as an object dates back to 1849; it was invented in 1849 by Walter Hunt. He literally made it in three hours to pay off a $15 debt. Yes, really. He even patented it — but then sold the patent rights for $400. Safe to say he may have second-guessed that one once the thing blew up.

What’s wild is that Hunt didn’t even think that this little hole in the coil would become a curious phenomenon more than 150 years later. But here we are.

The Best Kind of Everyday Engineering

To be honest, safety pins are an incredible functional design turn. They’re inexpensive, straightforward and somehow batshit useful. From fashion fixes and first aid to D.I.Y. projects and diaper duty (hello, vintage cloth diapers), they’ve weathered the test of time. And that’s in part thanks to the sort of small design details like those in a hole in a safety pin. It’s one of those “you don’t see it until you really see it” type of things.

Makes you think about how many more common tools have hidden features we never knew about, right? Like the hole in the pot handle (yup, that’s for your spoon), or that little groove you see at the bottom of plastic bottles (pressure control!). Engineering is truly lowkey amazing.

The Hole’s There for a Reason

If you’ve read this far, congrats; you’re now one of the 2% of humans who know what the hole in a safety pin is for. To recap:

It’s a crucial section of the spring mechanism.

It allows for tension and snap-back.

It is a touchstone during the manufacturing process.

It may even have some useful DIY applications if you’re crafty.

So next time you employ a safety pin — whether you’re mending a wardrobe malfunction or fastening it onto your punk jacket — thank that humble hole. It’s doing more than you knew it could.

And who knows, you might just gamify your chance of winning a random trivia game or impressing someone with your freakishly specific knowledge. Either way, you’re in the know, officially.

ADVERTISEMENT